It was all forged by hand. The hammers at the watercourses in the valleys produced the material. The further processing then took place in the small forges, where tools and equipment were made.

Drill drills were forged as a speciality, so to speak, and achieved a remarkable quality. In “Lievermängken” they were taken to the trading houses in the area, from where they found their way all over the world.

Friedr. Aug. Arnz enlarged the company and improved the factory facilities. Diligence and thriftiness made the continuous development possible. The production program already included drilling winches. Every year, as a result of the development of machine tools, improvements in production and new articles were introduced.

Variety is added to the tool range – with the drill winch and drill bit range, corner drill winches, hand drills and metal drill bits.

In the meantime, hand-held bench drills had also been developed. The Regulateur drills were introduced, which had automatic feed. They were sold all over the world and were protected by a German Reich patent.

The rapid technical progress, especially in the construction of high-quality machine tools, made the further development of the articles possible. New inventions also gave them a completely new face. For example, drilling winches were manufactured with a push-button ratchet, which was protected by a DR patent. Furthermore, multi-speed hand drills with a fully enclosed gear box and bench drills with several speeds and a fully enclosed gear box and adjustable, automatic feed, which were also protected for the company.

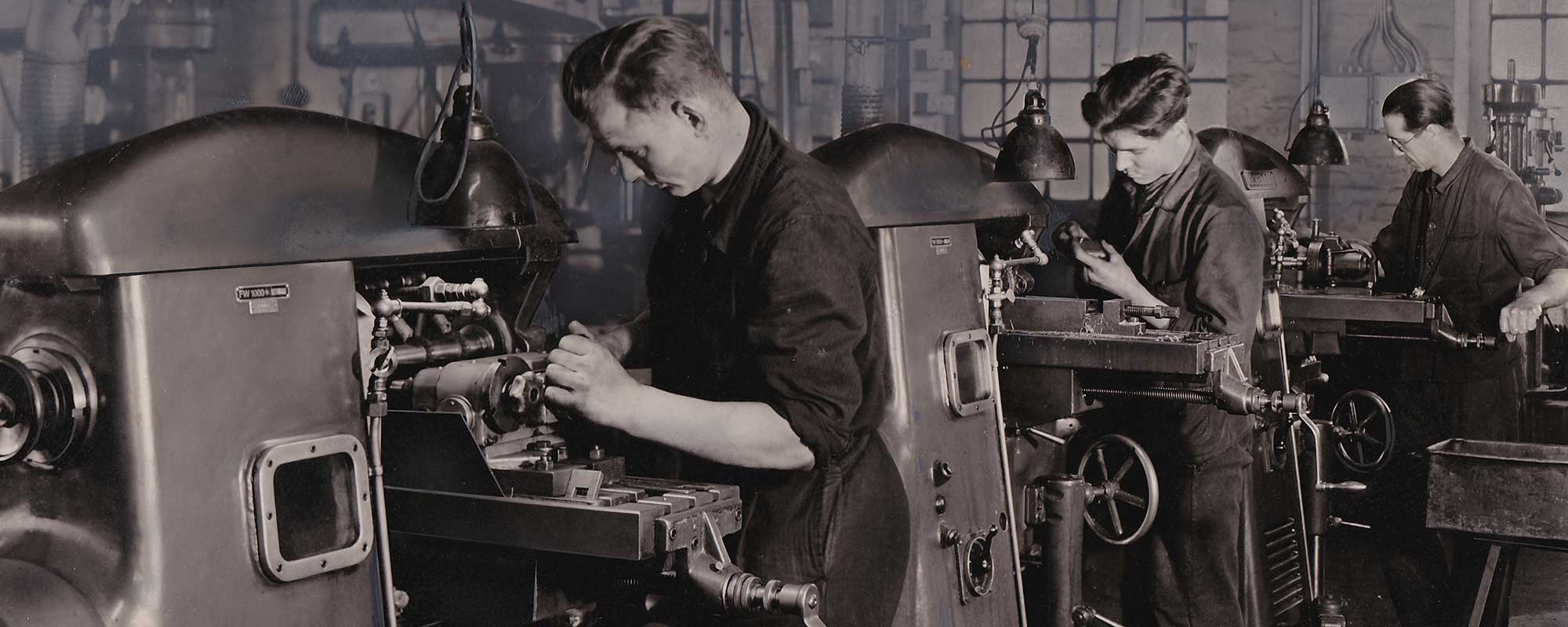

The company itself was converted to serial production. The production of the first electrically powered drill fell into this period.

The 3rd generation: The sons of Ernst and August Arnz joined the company after their apprenticeship.

And the 100th anniversary. The founder and his sons from the 2nd generation have long since passed away, but in their spirit, with the same diligence and thrift, the heirs in the 3rd and now more recently also in the 4th generation are creating.

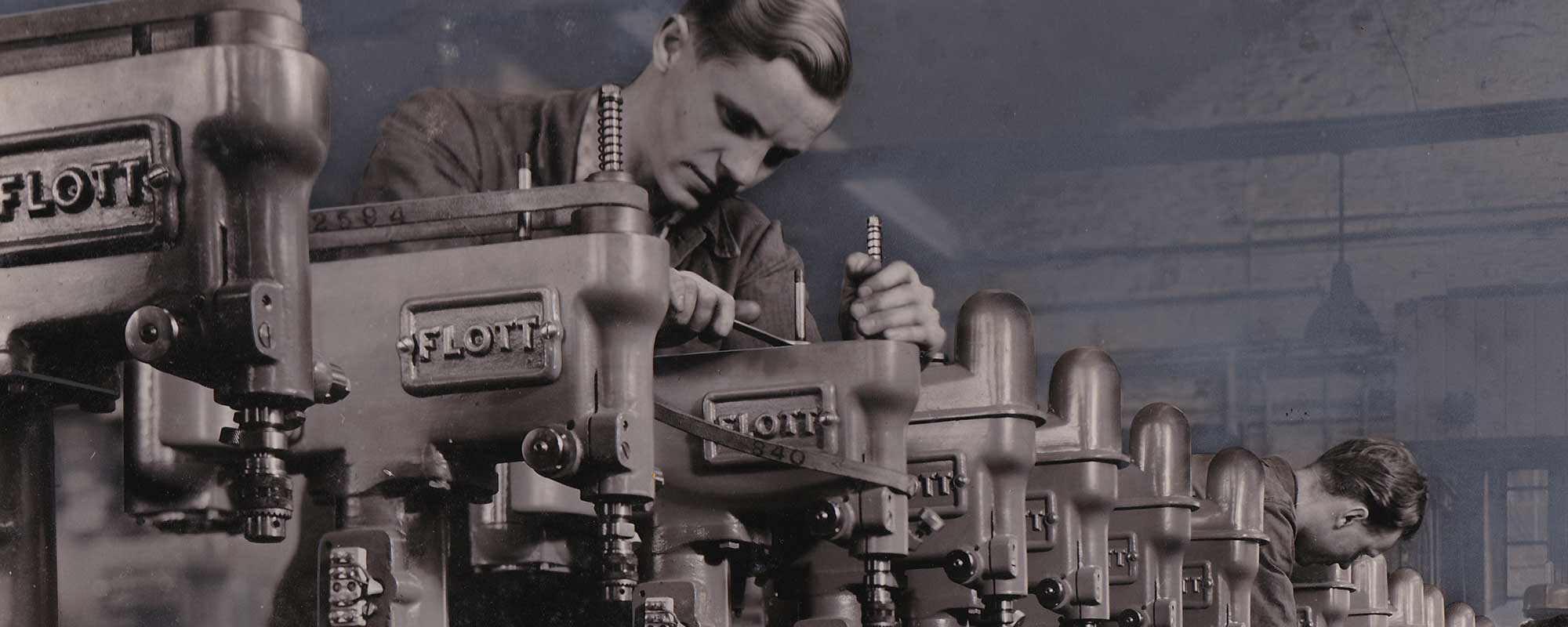

The company works with the most modern machines and with the most advanced production methods. The factory management competes with its old faithful skilled workers in the pursuit of quality and quantity. Solid, true to gauge production of all individual parts is one of the secrets for the uniformity of “FLOTT” products. Besides hand tools, it is the electric drills and grinders that leave the factory in large series.

This is how the “FLOTT” products became true branded articles with all the advantages that distinguish branded articles.

The reboot. With the financial crisis at the beginning of the year, sales had collapsed. Employees lost their jobs. Insolvency was unavoidable. But already in the middle of the year, the founding family ventured a new start. The good reputation and the brand name known in Europe were important for the new start. Flott tabletop or floor standing drilling machines are considered indestructible. They can be found in many workshops, training centres and production halls.

After the restart, the company is again one of the largest in the market. New products, such as a globally unique bench drill, in which drilling and thread cutting are controlled completely electronically, as well as the PlusSeries Stärken, which was launched in 2019, further strengthen the good market position.

A company with tradition. And future.